Flame spraying is a coating process using heat. A flame produces heat which is used to melt the thermal spray material, normally in powder, wire, or ceramic rod form. The molten particles are then propelled onto the surface to be sprayed, compressed air is used on the wire flame spray so that the molten particles are atomized and then propelled onto the substrate. When using the powder flame spray, the metal or ceramic powder particles are softened by the flame, then this softened powder is sprayed onto the surface to be coated by the use of the flame gases through the nozzle.

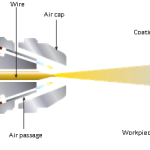

- Wire Flame Spray

wire flame spray

With the wire flame spray process, the wire spray material is melted in a gaseous oxygen-fuel flame. The fuel gas can be acetylene, propane or hydrogen. The wire is fed concentrically into the flame, where it is melted and atomized by the addition of compressed air that also directs the melted material towards the workpiece surface.

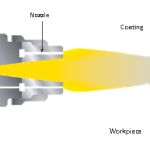

- Powder Flame Spray

powder coating

This coating process is based on the same operational principle as the wire flame spray process, with the difference that the coating material is a spray powder. Thus, a larger selection of spray materials is available, as not all spray materials can be manufactured in wire form.

In Ceramic coating, the feedstock material is fed continuously to the tip of the spray gun where it is melted in a fuel gas flame and propelled to the substrate in a stream of atomizing gas. Common fuel gas is acetylene. Air is typically used as the atomization gas.

Equipment: Ceramic coatings on pump equipment

Name of the part: Ceramic Coated Sleeves and Plungers

A major expense associated with pump operation is the replacement of sleeves/plungers.

Wear on these components necessitates:

1) Frequent packing adjustment to compensate for dimensional changes caused by wear.

2) Packing material failure due to sleeve surface roughness.

3) Premature pump stoppage due to leaks.

Abrasion, Corrosion, and friction are the main causes of the problem

The Solution we provide Coatings that provide a long-lasting wear-resistant surface using ceramic oxides or metallic carbides. We have a robotic Plasma transferred arc system (PTA) and flame spray equipment to apply coatings of tungsten carbide in a nickel chrome boron matrix and chromium oxides. The coating thickness is selected based on application wear potential and varies from 0.5mm to 1.5mm in thickness. For severe wear applications, PTA coated sleeves last longer.

The Compositions used in ceramic coating are Chromium oxide, Alumina Titanium, Zirconia, Nickel alloys, Aluminium Bronze.

Industries in which these parts are used are Thermal power plants, Sugar industries, Oil and gas sector and chemical process plants. These are our major consumers.

Distributor Shaft

Ceramic Coated Roll

Coating on Rotor Assembly